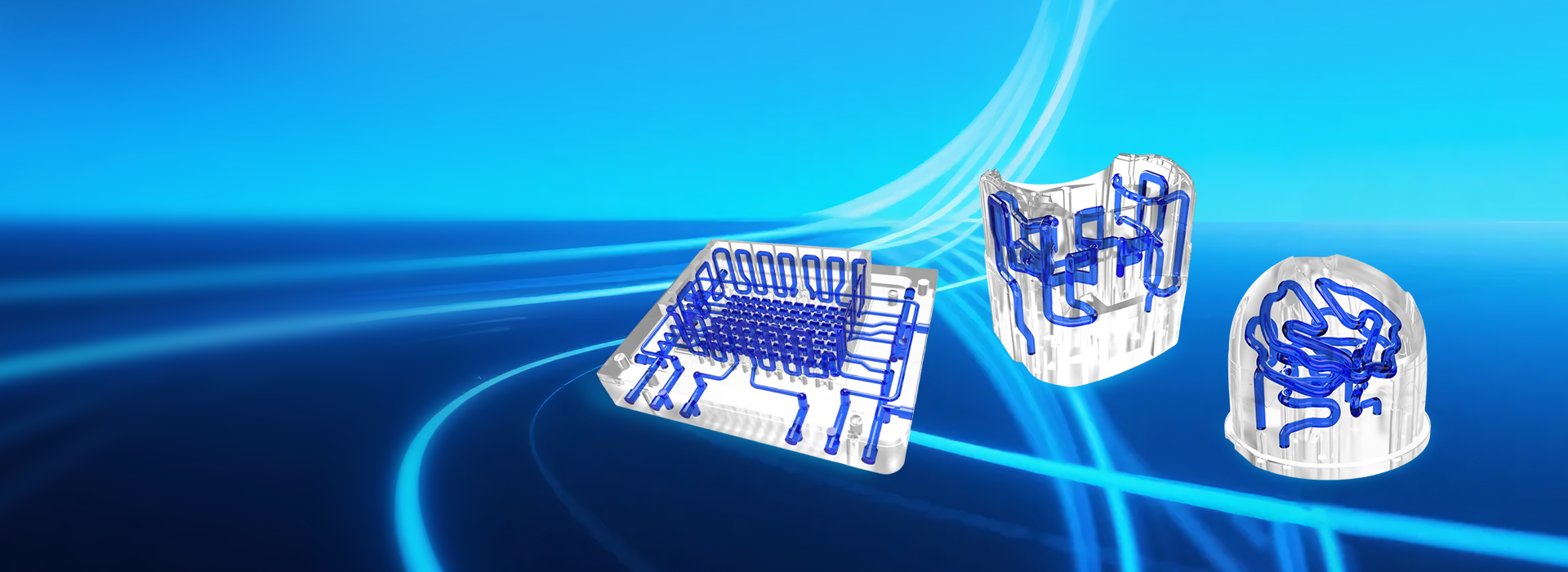

Product Overview

The MoldMeta Conformal cooling system is specially designed for the mold industry to optimize mold temperature control, enhance production efficiency, and improve product quality. Through precise temperature adjustment, the system helps the mold cool more evenly, reduces production cycles, and ensures the mold's accuracy and durability.

Key Features

Precise Temperature Control: Real-time monitoring and adjustment of mold temperature, ensuring uniform distribution and effectively preventing overheating or uneven cooling.

Enhanced Production Efficiency: Reduces cooling time, accelerates the mold production process, and lowers production costs.

Extended Mold Life: Efficient cooling system effectively reduces mold wear and extends service life.

Energy-Saving and Environmentally Friendly: Utilizes advanced cooling technology to reduce energy consumption and minimize environmental impact.

Enhanced Production Efficiency: Reduces cooling time, accelerates the mold production process, and lowers production costs.

Extended Mold Life: Efficient cooling system effectively reduces mold wear and extends service life.

Energy-Saving and Environmentally Friendly: Utilizes advanced cooling technology to reduce energy consumption and minimize environmental impact.

Applications

Injection Molding: Helps injection molds cool quickly and uniformly, improving production efficiency and product quality.

Aluminum Die Casting Molds: Ensures even mold temperature during the aluminum die casting process, preventing thermal cracks and uneven cooling.

Die Casting and Precision Casting: Optimizes temperature control to ensure the precision and surface quality of precision castings.

Plastic Molding: Maintains mold stability during high-temperature molding processes, improving molding accuracy.

Aluminum Die Casting Molds: Ensures even mold temperature during the aluminum die casting process, preventing thermal cracks and uneven cooling.

Die Casting and Precision Casting: Optimizes temperature control to ensure the precision and surface quality of precision castings.

Plastic Molding: Maintains mold stability during high-temperature molding processes, improving molding accuracy.

Technical Specifications

Cooling Capacity: Powerful, suitable for most products.

Control Accuracy: Temperature control accuracy up to ±0.1°C, ensuring precise adjustments.

Applicable Voltage: Supports 220V / 380V power input.

Operating Temperature Range: Stable operation between 0°C and 80°C.

Material: High heat-resistant material, designed for high-temperature environments, ensuring long-term stable operation.

Control Accuracy: Temperature control accuracy up to ±0.1°C, ensuring precise adjustments.

Applicable Voltage: Supports 220V / 380V power input.

Operating Temperature Range: Stable operation between 0°C and 80°C.

Material: High heat-resistant material, designed for high-temperature environments, ensuring long-term stable operation.