Services we can provide

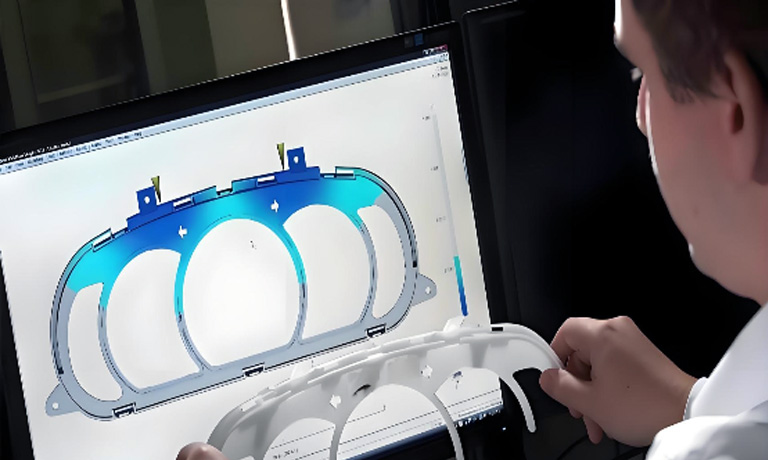

We provide services for feasibility analysis, mold flow/thermal simulation, cooling system design, 3D printing services, base frame/datum machining, and precision finishing processes, delivering end-to-end manufacturing excellence for 3D mold component printing.

Our Equipment

-

Makino EDM EDGE3i/EDNC6i

Qty : 9

Max. Machining Range(mm) : 500*450*240

Tolerance(mm) : ±0.002

Speed(rpm) : 42000Makino EDM EDGE3i/EDNC6i

-

Roders RXP601DSH 5-Axes

Qty : 9

Max. Machining Range(mm) : 500*450*240

Tolerance(mm) : ±0.002

Speed(rpm) : 42000Roders RXP601DSH 5-Axes

-

Roders RXP500 3-Axes

Qty : 9

Max. Machining Range(mm) : 500*450*240

Tolerance(mm) : ±0.002

Speed(rpm) : 42000Roders RXP500 3-Axes

-

Makino Wire CUT U6

Qty : 9

Max. Machining Range(mm) : 500*450*240

Tolerance(mm) : ±0.002

Speed(rpm) : 42000Makino Wire CUT U6

-

MITSUBISHI EDM EA8PS

Qty : 9

Max. Machining Range(mm) : 500*450*240

Tolerance(mm) : ±0.002

Speed(rpm) : 42000MITSUBISHI EDM EA8PS

-

HEXAGON GLOBAL S 575

Qty : 9

Max. Machining Range(mm) : 500*450*240

Tolerance(mm) : ±0.002

Speed(rpm) : 42000HEXAGON GLOBAL S 575

-

HEXAGON Metus452F

Qty : 9

Max. Machining Range(mm) : 500*450*240

Tolerance(mm) : ±0.002

Speed(rpm) : 42000HEXAGON Metus452F

-

Grinder Okamoto ACC350

Qty : 9

Max. Machining Range(mm) : 500*450*240

Tolerance(mm) : ±0.002

Speed(rpm) : 42000Grinder Okamoto ACC350

Material Introduction

| Material | Timax1052 | Timax2036 | Timax2050 | Timax2054 | Timax2056 | Timax4052 |

|---|---|---|---|---|---|---|

| Application | Injection mold component | Metal components, inspection tools, jigs | Thin-walled parts, open-type sprue bushings, mold cores, inserts, sliders, etc. | Lifters, sliders, core pulls, valve-gate bushings, wear-resistant plates | High wear/ corrosion- resistant mold components with fiberglass (GF), carbon fiber (CF), or corrosive additives | All die-casting mold components |

| Characteristics | Good toughness, easy to process, Wear-resistant, poor corrosion resistance | Corrosion- resistant, good weldability, high strength, high toughness, easy to process | Corrosion- resistant, wear-resistant, high toughness, high polishability | High wear resistance, corrosion-resistant, high toughness, high polishability | High hardness, corrosion-resistant, wear-resistant, high polishability, extremely high ductility and toughness | Excellent tempering resistance, good resistance to heat checking, cracking, thermalwear, and plastic deformation |

| Material Categories | Age-hardening steel | Stainless Steel | High-grade stainless tool steel | High-grade stainless tool steel | High-grade stainless tool steel | Hot work tool steel |

| Steel Equivalents | H13/8407/1.2344 | 316L | S136/1.2083 | Stavx/Mirrax/M333 | M333/M340 | DIEVAR |

| Hardness | Hardness range: HRC35-52 | ≤HRB90 | Hardness range: HRC35-50 | Hardness range: HRC35-54 | Hardness range: HRC35-56 | Hardness range: HRC35-54 |

| Recommend hardness : HRC48-52 | Recommend hardness : HRC48-50 | Recommend hardness : HRC50-54 | Recommend hardness : HRC52-56 | Recommend hardness : HRC50-52 | ||

| Compatible Base Materials | H13/8407/1.2344 | / | P20/718/718H/ S136/1.2083 | S136/FS636 | UNIMAX/S136/ 1.2083 | 8148/H13/DIEVAR |

| Material properties: Corrosion resistance | ★ ☆ ☆ ☆ ☆ | ★ ★ ★ ★ ☆ | ★ ★ ★ ★ ☆ | ★ ★ ★ ★ ☆ | ★ ★ ★ ★ ☆ | ★ ★ ★ ★ ☆ |

| Wear resistance | ★ ★ ☆ ☆ ☆ | ★ ★ ☆ ☆ ☆ | ★ ★ ★ ★ ☆ | ★ ★ ★ ★ ★ | ★ ★ ★ ★ ★ | ★ ★ ★ ★ ☆ |

| Polishability | ★ ★ ★ ★ ☆ | ★ ★ ☆ ☆ ☆ | ★ ★ ★ ★ ☆ | ★ ★ ★ ★ ☆ | ★ ★ ★ ★ ☆ | ★ ★ ★ ★ ☆ |

| Toughness | ★ ★ ★ ☆ ☆ | ★ ★ ☆ ☆ ☆ | ★ ★ ★ ★ ★ | ★ ★ ★ ☆ ☆ | ★ ★ ★ ★ ☆ | ★ ★ ★ ★ ★ |

| Ultimate hardness | ★ ★ ★ ★ ☆ | ★ ☆ ☆ ☆ ☆ | ★ ★ ★ ★ ☆ | ★ ★ ★ ★ ☆ | ★ ★ ★ ★ ★ | ★ ★ ★ ★ ☆ |

| High-temperature fatigue resistance | ★ ★ ☆ ☆ ☆ | ★ ☆ ☆ ☆ ☆ | ★ ☆ ☆ ☆ ☆ | ★ ☆ ☆ ☆ ☆ | ★ ☆ ☆ ☆ ☆ | ★ ★ ★ ★ ★ |

| Application Fields | Injection molds | Metal components, tooling jigs | Injection molds | Injection molds | Injection molds | Die-casting mold |

Case Stduies

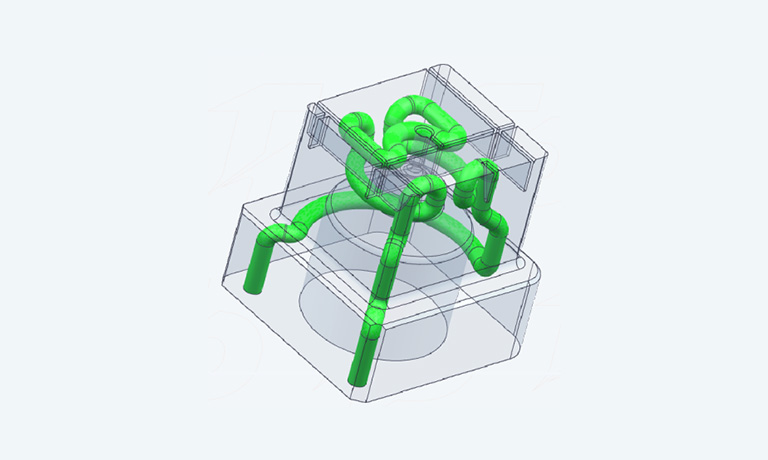

The Parameter

Part name : Automotive interior and exterior trim - front mold insert

Dimensions | mm (L*W*H) : 62.950x57.900x62.820

Technical difficulties : complex shape, waterway machining cannot be made, long cooling cycle

Printing material : T2054

Molding method : full printing

Molding surface appearance requirements : demolding polishing

Hardness requirements | HRC : 52-54

Number of waterways | Group : 1

Waterway inlet and outlet dimensions | mm : ∅5.00

Equivalent cross-sectional area | mm : ∅5.00

Cooling medium : water

Cycle improvement : 32.0%

Dimensions | mm (L*W*H) : 62.950x57.900x62.820

Technical difficulties : complex shape, waterway machining cannot be made, long cooling cycle

Printing material : T2054

Molding method : full printing

Molding surface appearance requirements : demolding polishing

Hardness requirements | HRC : 52-54

Number of waterways | Group : 1

Waterway inlet and outlet dimensions | mm : ∅5.00

Equivalent cross-sectional area | mm : ∅5.00

Cooling medium : water

Cycle improvement : 32.0%

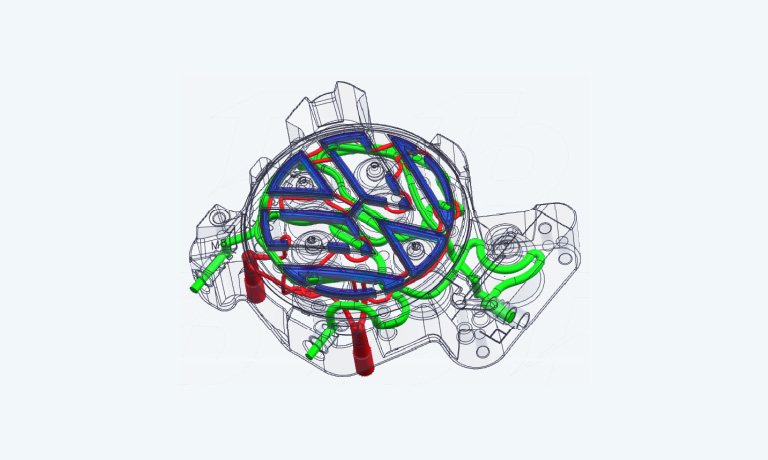

The Parameter

Part name : New energy vehicle logo-front mold insert

Dimensions | mm (L*W*H) : 156.800x194.130x64.48

Technical difficulties : Air trapped in the product, unbalanced temperature at the glue inlet, long cooling time

Printing material : T2050

Molding method : Grafting printing

Molding surface appearance requirements : A2

Hardness requirements | HRC : 48-52

Number of waterways | Group : 2 (1 set of air circuits)

Waterway inlet and outlet dimensions | mm : ∅5.00 (air circuit ∅3.50)

Equivalent cross-sectional area | mm : ∅5.00 (air circuit ∅3.50)

Cooling medium : water

Cycle improvement : 42.0%

Dimensions | mm (L*W*H) : 156.800x194.130x64.48

Technical difficulties : Air trapped in the product, unbalanced temperature at the glue inlet, long cooling time

Printing material : T2050

Molding method : Grafting printing

Molding surface appearance requirements : A2

Hardness requirements | HRC : 48-52

Number of waterways | Group : 2 (1 set of air circuits)

Waterway inlet and outlet dimensions | mm : ∅5.00 (air circuit ∅3.50)

Equivalent cross-sectional area | mm : ∅5.00 (air circuit ∅3.50)

Cooling medium : water

Cycle improvement : 42.0%

Start Your New Instant Quote

Start Your New Instant Quote All uploads are secure and confidential.

All uploads are secure and confidential.